- Achieved Results :

- Emission Reduction

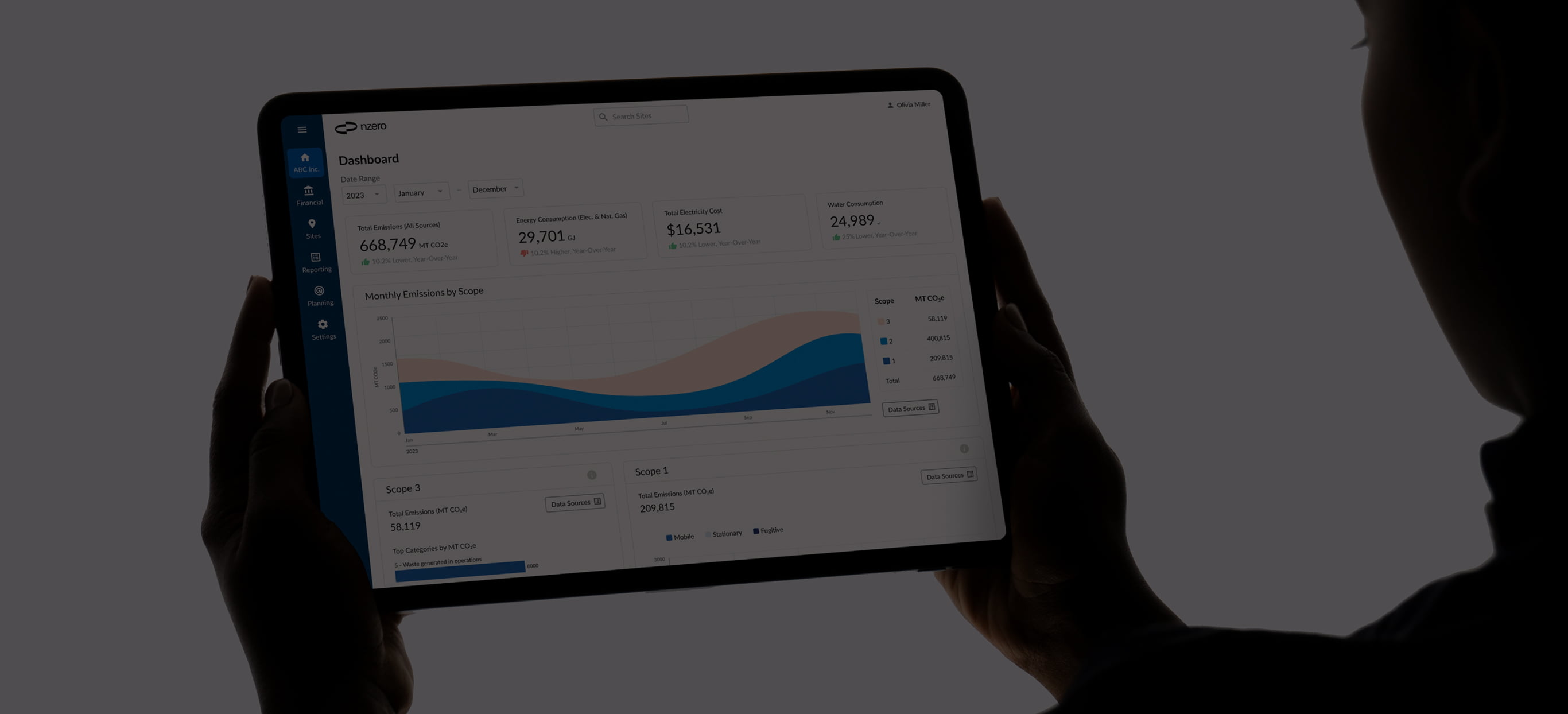

A First Step Toward a 50% GHG Reduction: Gaining Visibility into Energy Use with NZero

Published February 18, 2026

| Challenge ・Monthly energy data was shared only between the Finance and Maintenance teams, limiting broader internal use. ・Without context on whether electricity consumption was high or low, the company was unable to move forward with analysis or concrete actions. Solution ・NZero, an AI-powered energy management cloud platform Impact ・Enabled data-driven evaluation of renewable energy options and the use of environmental certificates. ・Established a common set of metrics to support plant level decision making aligned with the group’s decarbonization goals. |

About Austin Tri-Hawk Automotive(ATA)

- Business Overview

Austin Tri-Hawk Automotive (ATA) is an automotive parts manufacturer based in Indiana, United States. As a consolidated subsidiary of G-TEKT Corporation, ATA plays a key role in supplying the North American market.

- Products and Operations

ATA manufactures automotive structural components used around the driver’s area, pillars, and floor sections—parts that are essential to vehicle strength and safety.

- Strengths

With large-scale press equipment and advanced automated welding technologies, ATA produces high-precision structural components at scale and maintains continuous supply to global automakers such as Honda and Subaru.

Plant-Level Energy Management Toward a 50% GHG Reduction by 2030

The driver behind Austin Tri-Hawk Automotive (ATA)’s more structured approach to sustainability was a clear group wide target: reducing GHG emissions by 50% by 2030. To contribute to this goal, they recognized the growing need to define concrete actions at its North American operations.

While the company was already tracking electricity consumption, it lacked visibility into whether its energy use was high or low relative to its operations, as well as insight into underlying trends. Energy data was primarily managed by the accounting team and shared monthly with the maintenance team, but this process focused on reporting numbers rather than enabling analysis or improvement discussions.

To move beyond basic reporting, they began exploring an energy visibility solution that could serve as a foundation for more informed decision-making. The company first learned about NZero through a networking event held in Indiana, where it was introduced to the platform’s ability to continuously track and analyze energy use.

The decision to adopt NZero was ultimately driven by its practical value proposition. They found that the solution offered a realistic balance between cost and functionality, along with clear, thoughtful explanations tailored to the company’s operational scale and challenges. Based on this alignment, they decided to move forward with the implementation of NZero.

Using NZero as a Guide Toward Decarbonization Goals

After implementing NZero, they began treating energy use not as numbers to be shared, but as information to support decision-making. The platform made it possible to identify usage patterns and fluctuations that had previously gone unnoticed, establishing a common factual basis for internal discussions.

In Indiana, where dependence on fossil fuels remains high, accurately understanding current conditions is essential to evaluating realistic options. By automatically capturing hourly data on electricity, gas, water, and steam, NZero provided clear visibility into energy consumption. With this data in place, we are now considering concrete measures such as rooftop solar leasing and the use of environmental certificates.

Looking ahead, they plan to use NZero as a core reference for internal energy management, balancing financial performance with environmental responsibility while working toward becoming a model manufacturing operation.

What Sets Austin Tri-Hawk Automotive Apart

Austin Tri-Hawk Automotive (ATA) plays an important role in G-TEKT Corporation’s North American operations, manufacturing automotive structural components at its Indiana-based facility. Leveraging large-scale press equipment and advanced automated welding technologies, the company produces critical safety related components used around the dashboard area and vehicle pillars, parts that are directly linked to vehicle safety.

Backed by technical expertise drawn from its global network, ATA operates under a rigorous quality management system that supports both vehicle safety and weight reduction. Through this production framework, the company maintains a stable supply to the North American manufacturing operations of global automakers such as Honda and Subaru.

Company Profile

・Company Name Austin Tri-Hawk Automotive(ATA)

・Industry Automotive parts manufacturing

・Number of Employees 430

・Headquarters Austin, Indiana 47102, U.S.A

For sustainability

leaders, by

sustainability leaders.

Discover More

For sustainability

leaders, by

sustainability leaders.

Discover More

control of your

energy future?

Stop guessing and start making data-driven decisions. See how NZero can transform your energy management and decarbonization strategy.

Request Your Personalized Demo